Eastman Exports

(A Division of Eastman Exports Global Clothing Pvt Ltd.,)5/591, Sri Lakshmi Nagar

Pitchampalayam, Pudur

Tirupur - 641 603,

Tamilnadu.

Operations

Right from yarn to making fabrics of different quality in cotton, Synthetic, blends like viscose / modal, Polyester, melanges, yarn dyed, organic, slub, Compact yarn etc., produced in house in huge knitting and state -of-the-art dyeing facilities...

- Fashion Innovation

- Design Studio

- Flexibility

- Shorter Lead Time

- Ability to process Orders of Any Quantity

- Design & Sampling

- Spinning

- Knitting

- Accessories

- Embroidery

- Dyeing & Finishing

- Printing

- Production Facilities

- Testing Lab

Design & Sampling

We have a state of the art design studio equipped with.,

Virtual Fit Simulation

- 3 dimensional fit simulation software for virtual fitting and draping of the garment created using CAD patterns.

- The measurements of the fit model and garments spec is given by the client.

- This helps us in speeding our approval of fit, Viewing colour combination to near perfection and interaction with the customers, online or by video conferencing.

- The software also lets you to view how the products will look even before it is made.

Graphic Design and Forecasting

- We have in -house dedicated design team to do research on print graphics/embroidery and printing techniques of Speciality Garment washes.

- We have closely monitoring with global seasonal requirement through our market intelligent network through online subscriptions of an international services

- We also have a team of graphic Artists for all hand created designs.

Spinning

Our Spinning facility houses modern machines from LMW, India & Schlafhorst, Germany. We also produce blended and organic yarn to cater to our socially responsible clientele. We also Produce Compact yarn, Slub yarn, Fair Trade, BCI, Organic Cotton, ETI.

Autoconer

Our mill is equipped with high efficient autoconers which have the capacity to produce 45 tones per day.

The sophisticated machines are much efficient in terms of productivity, energy efficiency and environmental friendliness by reducing fibre dust through self cleaning technologies.The autoconer delivers uniform and high quality packages.

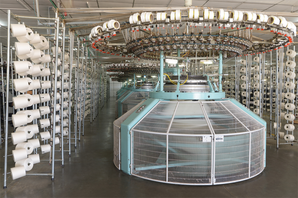

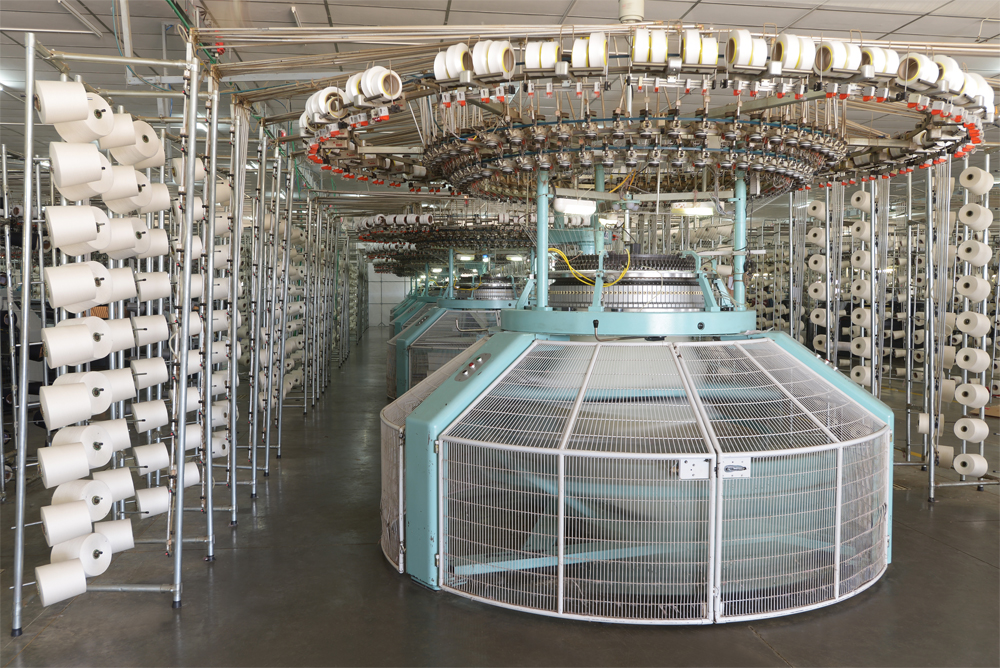

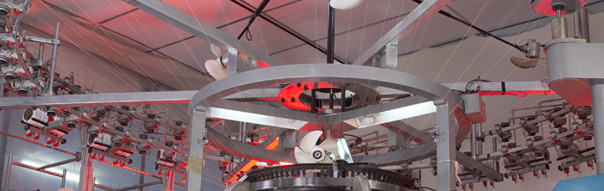

Knitting

Our knitting plants, with Circular & Flat Knitting machines imported from Europe and Asia knit a varieties of fabrics – Jersey, Rib, Interlock, Pique, Feeder & Auto Stripes, Jacquards, with Lycra, flat knit collars, waffle, Fleece in all gauge and feeders.

The entire fabric produce in house is suitable enough capacity to meet our requirement .

We are capable of producing all kind of specialty fabrics and performance technical fabrics.

Collar knitting

Accessories

Our elastic division manufactures both knitted and woven elastic by using Comez (Italy) and Jacob Muller (Switzerland) machines. We have the facility of printing barcodes, price tickets, carton stickers and labels, and packaging materials. We have in house EDI (Electronic Data Interchange) facility also.

Embroidery

Our embroidery divisions have sophisticated Japanese and German machines using CAD/CAM designing, which enable mass scale execution of intricate embroidery in upto 9 colours with, Laser cut & Sequence, with latest technology.

Dyeing & Finishing

To process cotton, Polyester and blended fabrics, we have the advanced HTHP cheese dyeing division. Equipped with machinery from Thies, Germany, Brozoli Italy. Our OEKO-TEX and GOTS certified fabric dyeing division has a modern Effluent Treatment Plant & Reverse Osmosis Technology, and Biological treatment technologies and Nano Technology reinforcing our commitment to eco-friendly practices. (Zero Liquid Discharge)

Capacity

- Fabric Dyeing - 60 Tonnes / day

- Yarn Dyeing – 10 Tonnes / day

For fine finishing, we have techniques like sueding / brushing and performance finishes that include antimicrobial, UV, wicking and so on. Our compacting division has tubular and open-width machines like Albrecht from Germany and Ferraro from Italy. The Ehardt and Leimer machines are available for auto slit opening. The Montex, Ewha open-width stentering machine with Bianco computerized weft straightener enables fabric straightening. We have multiple washing options like silicon wash, stone wash, enzyme wash, bio-polish,vintage washes, etc. To process knitted and woven fabrics, the fabric controlled shrinkage relax dryer machine from Alea, Italy is available.

Printing

Printing is one of our chief strength. Equipped with two rotary printing machines, we produce innovative and trendy designs in pigment, reactive and discharge up to 10 colours with engineered repeat options.

All Over Rotary Printing capacity – 12 Tonnes / day

Our garment spot printing division facilitates pigment and Plastizol prints on Sroke, Askme, MHM machines from Austria, Portugal, Taiwan and India. We are also capable of thermal transfer printing, flock printing and specialized prints using latest print techniques as Sublimation Printing and Digital Printing.

Our printing machines are capable of creating trendy and delicate designs and it is one of our biggest fortes.

Production Facilities

Our production facilities are state of the art factories equipped with the latest in technology used in garment manufacturing right from Gerber cutting to packing comprising Japanese, European & American machineries.

A strong Infrastructure enables us to meet the customers requirements even before the proposed deadline.

Combining the best craftsmanship and contemporary machinery like Lectra, Gerber and Tuka Tech Automatic, a high degree of precision in cutting is achieved.

We have the best in class sewing machines like Juki, Pegasus, Siruba, Orbito, Brother, Hasima, Sintex, Eastman, etc. from Japan, Singapore, Taiwan and Hong Kong.

Our Factories are awarded with Green Certificate (Eco Friendly)

Precision

Supply Chain Management

An effective Supply Chain Management is the hallmark of our efficient operations. We have a hi-tech Automatic Re-ordering System (AROS) that enables us to monitor sales in stores, based on which we maintain our inventory levels. So, right from procurement of raw materials to dispatching the finished goods, logistics support makes sure we deliver on time, every time.

We are also capable & handling VMI (Vendor Management Inventory), Automatic Reordering system (AROS) and shorter lead time programs.

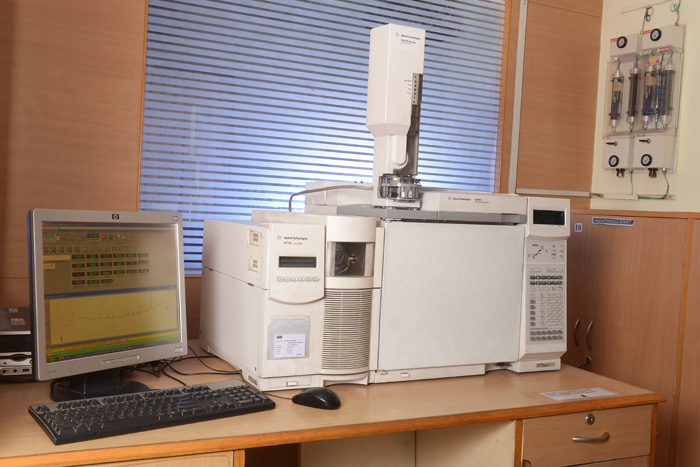

Laboratory

Right through our production processes, we have rigorous testing of physical and chemical parameters to ensure zero-defects. The balanced combination of supervisory personnel and sophisticated machines in laboratories could provide competent test results. The laboratory management system being accredited as per IEC/ISO 17025 and being approved by various brands. The laboratories have wider test capability to handle specific confirmation, performance/durability and safety tests including analysis of various organic toxins including azo dyes, phthalate content, chlorophenols, chlorobenzenes/toluene etc.

The continuous improvement to generate internal technical competence which in turn supports the manufacturing very effectively across the processes in various technical aspects.