Eastman Exports

(A Division of Eastman Exports Global Clothing Pvt Ltd.,)5/591, Sri Lakshmi Nagar

Pitchampalayam, Pudur

Tirupur - 641 603,

Tamilnadu.

Commitment

At Eastman, our commitment takes precedence over everything else. We believe our success is the result of our commitment to product quality, timely delivery, the environment and our human resources. All our products comply to REACH standards.

At Eastman, we pledge to care for the society & the environment. The WRAP certification testifies us as a responsible apparel producer. Endorsing our commitment to the environment is the ISO 14001, Oeko Tex Standard – 100 and Eco-tex. Our Social Accountability Management System complies with the SA 8000 standards. The reduced water consumption in our dyeing unit, following energy saving means and reduced carbon emission reinforce our responsibility. We are certified to produce all blends of Organic Cotton products, BCI known as sustainable textile products, which further testify our commitment to the world we live in.

Eastman Exports believes ‘Quality First’ in each and every action. A top-notch team of professionals consistently examine the intricacies of quality management through online. Right from the procurement of raw materials to the manufacturing of end product, they use latest quality technology system and methods so as to meet the needs of the buyer. We have our own lab facility accredited by various brands to monitor quality at different levels.

Right through our production processes, we have rigorous testing of physical and chemical parameters to ensure zero-defects.

As a people-centric organization, we ensure a proper work-life balance for our people. Our compensation standards comply with statutory norms so our employees can lead secure and satisfied lives. We also organize professional development programmes that allow them to keep pace with prevalent trends and techniques.

Our facilities have been Certified with ETI, BSCI, Oeko Tex- I & II, Sedex, GOTS(Organic), WRAP, BCI, ISO 9001-2004, ISO 14001-2008, SA-8000, Disney(FAMA).

Flexibility

We have flexibility of handling any kind of volumes for all our product categories.

Delivery

Supply Chain Management

An effective Supply Chain Management is the hallmark of our efficient operations. We have a hi-tech Automatic Re-ordering System (AROS) that enables us to monitor sales in stores, based on which we maintain our inventory levels. So, right from procurement of raw materials to dispatching the finished goods, logistics support makes sure we deliver on time, every time.

We are also capable & handling VMI (Vendor Management Inventory), Automatic Reordering system (AROS) and shorter lead time programs.

Sustainability

We believe in sustainable bright future, with our continuous rapid transformations sustainability remains as core of our business. And working towards more sustainable future; As a fast responsive manufacturer we ahead with future beyond thinking and continuous improvement in environment management system all the time. Our operations focus on reducing the environment impact and reducing the foot print in every aspect/process.

Sustainable Coalition & Higg Index

Eastman is a member of Sustainable Apparel Coalition. By becoming a member in sustainable apparel coalition we will effectively utilize the Higg Index to measure our Environment and Social impacts. Also, SAC gives platform for collaboration and knowledge sharing platform which can accelerate the sustainability development at Eastman.

As a leader in the apparel industry Eastman proud to initiate circular economy which bring major relief to the environment. Eastman can able to produce certified recycled products made from the polyester, cotton and regenerated cellulose fibers like lyocell made from recycled polymer. Contact us to take part on the combat against the global warming and other environment impact made by human.

Our Sustainability Objectives

- Reducing the environment impact.

- Reducing the foot print.

- Optimisation of natural resource utilisation.

- Reduce/Optimise, Reuse & Recycle.

- Being Ethical.

- Continuous Improvement.

Join with us!

As most efficient manufacturer of organic clothing in sustainable way our strategy and policies focus ahead of environment requirement of product supply chain. We are highly committed to improve the climate impact together with our partners all the time.

We believe in greener and sustainable future; we dress the world with more green manufacturing. Join with us for a better world and environment!

Higg Achievements

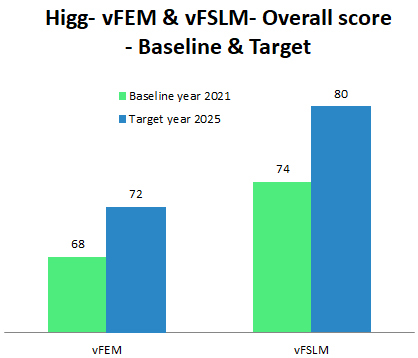

We at Eastman as a member of SAC- Measure, Quantify, Monitor, Implement strategies & reporting Sustainability in environment and social aspects through Higg FEM and FSLM tool respectively thereby driving business through reducing risk and uncovering efficiencies.

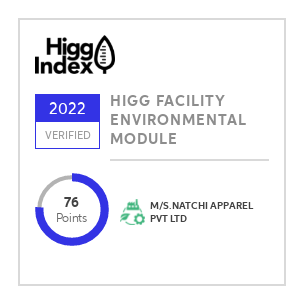

Our Score Card here defines our environmental performance (vFEM) of 12 Tier 1 facilities

Higg Baseline and Targets

Baseline and Target has been set by considering our 12 Tier 1 Facilities and 16 Tier 1 & 2 facilities for vFEM and vFSLM respectively.

We are in the process of implementing strategic plans to achieve our Commitments and Target by taking knowledge and guidance from leading service providers/ stake holders like SAC, ZDHC, BHIVE, STS, etc.

| S.No | Facility Name | Higg ID |

|---|---|---|

| 1 | ANAND TEXTILES LLP | 11819 |

| 2 | SRI ARUL TEX LLP | 31008 |

| 3 | INDIA DYEING MILLS (P) LTD | 31012 |

| 4 | NAKUALN TEX LLP UNIT 2 | 136216 |

| 5 | NAKULAN TEX LLP | 31047 |

| 6 | M/S NATCHI APPAREL PVT LTD | 50227 |

| 7 | NATCHI APPAREL PVT LTD - PRINTING DIVISION | 145684 |

| 8 | RODAMINE APPAREL INDUSTRIES (P) LTD - SHED NO. 20 | 46118 |

| 9 | SHRI AJAY KNITTEX LLP | 1726 |

| 10 | SRI SENTHIL BALAJI TEX LLP UNIT - II | 141007 |

| 11 | DHANA TEXTILES LLP | 31046 |

| 12 | DHANA TEXTILES LLP UNIT -2 | 129409 |

| 13 | ELANGOVAN TEX LLP | 31010 |

| 14 | JEGA GARMENTS LLP | 31011 |

| 15 | YELLOW JERSEYS LLP | 31009 |

| 16 | M/S.RODAMINE APPAREL H1H2 DIVISION OF EASTMAN SPINNING MILLS P LTD | 46116 |

| S.No | Facility Name | Higg ID |

|---|---|---|

| 1 | M/S.NATCHI APPAREL PVT LTD | 50227 |

| 2 | SHRI AJAY KNITTEX LLP | 1726 |

| 3 | M/S.RODAMINE APPAREL H1H2 DIVISION OF EASTMAN SPINNING MILLS P LTD | 46116 |

| 4 | JEGA GARMENTS LLP | 31011 |

| 5 | YELLOW JERSEYS LLP | 31009 |

| 6 | ELANGOVAN TEX LLP | 31010 |

| 7 | DHANA TEXTILES LLP UNIT-2 | 129409 |

| 8 | DHANA TEXTILES LLP | 31046 |

| 9 | SRI ARUL TEX LLP | 31008 |

| 10 | ANAND TEXTILES LLP | 11819 |

| 11 | NAKULAN TEX LLP | 31047 |

| 12 | NAKULAN TEX LLP UNIT 2 | 136216 |

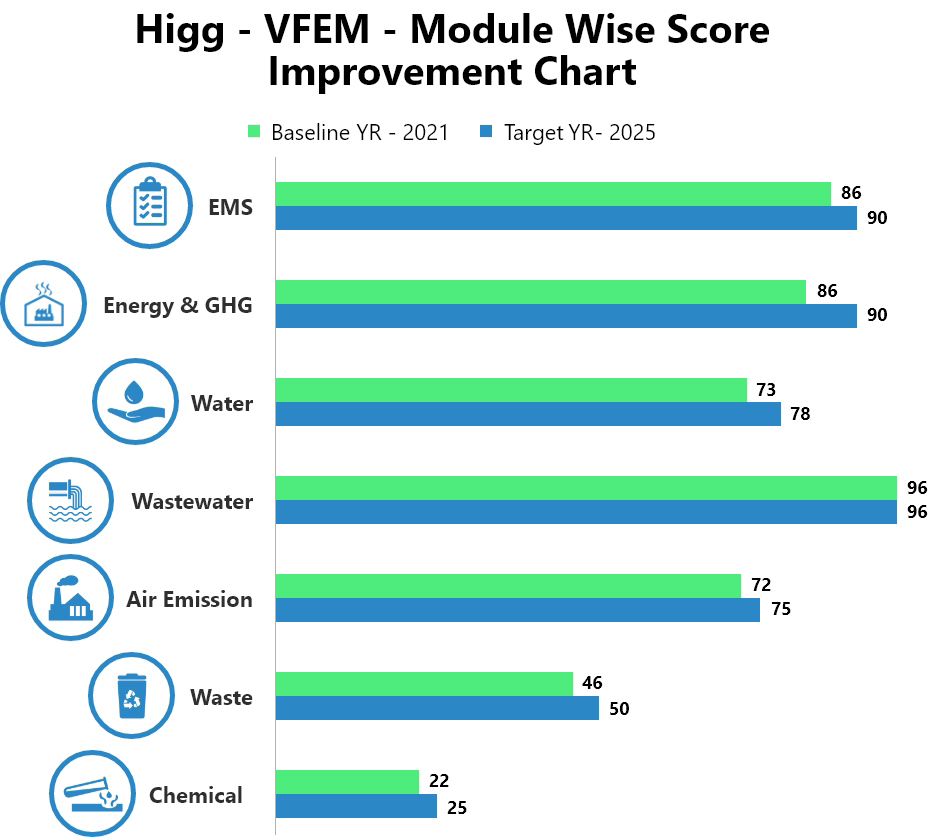

vFEM module wise Baseline and Targets for 12 Tie 1 Facilities

Environmental Management System:

We are effectively managing environmental impacts in our entire supply chain by implementing and utilizing Environmental management system (ISO14001) and thereby focusing on improvement targets by setting up goals & objectives and working towards it. We are in a path to reduce our environmental footprint by identifying, prioritizing, and managing environmental risks & opportunities.

Energy & GHG:

Towards our contribution to reduce Green House Gas Emission related to fuel combustion including Purchased Electricity, we have set reduction targets and working on to reduce energy consumption by implementing energy-efficient practices such as switching to LED lighting, optimizing production processes, using renewable raw materials and investing in renewable energy sources. We have already committed to SBTi and progressing towards publishing Emission Targets.

Water and waste water:

As far as water is concerned, our company has set targets and strategies and also implemented a range of measures to reduce ground water consumption by installing water-efficient methodologies and machineries, recycling water wherever possible, and improving water discharge quality by treating wastewater before it is being discharged.

Air Emission:

We are tracking pollutants from point and non-point source emissions and using control devices to improve air emission quality. We have implemented measures to reduce greenhouse gas emissions from non- combustion sources including less GWP gas utilization in refrigerants. Currently we are in Strategic level and working on to achieve Aspiration level as per higg.

Waste:

Waste management is a key sustainability activity in the apparel industry and it has significant environmental impact. Our reduction target in waste module has been projected by focusing and implementing waste reduction measures like reducing packaging waste, composting food waste, upcycling textile fabric waste, etc.

Chemical management:

Chemical management is a critical aspect of Eastman Exports' sustainability efforts, we have implemented a Chemical Management System to track and manage the use of chemicals across its operations. Ensuring safer chemistry, we are using the ZDHC Gateway and The Bhive tool for dyeing & printing facilities and we are proud to say that we are using 100% ZDHC compliance product only. As far as Tier 1 (Garmenting) facilities are concerned we are working on improvement targets.